ROTOR TECHNOLOGY

Rotor blades - Wings in the sky - durable, lightweight, efficient.

The aerodynamic and geometric design of the rotor blades is carefully considered to achieve the optimum ratio between lift and drag forces, allowing the helicopter to achieve the desired flight and operational characteristics.

The design of the rotor blades must be strong, rigid and durable enough to withstand the forces generated by rotational, mass, inertial, frequency and aerodynamic loads.

Modern technology and materials allow rotor blades to be manufactured with high strength and durability, while at the same time high inertia can be achieved at low mass. This, together with advanced aerodynamics, leads to better helicopter performance, lower fuel consumption, higher efficiency and longer rotor blade life.

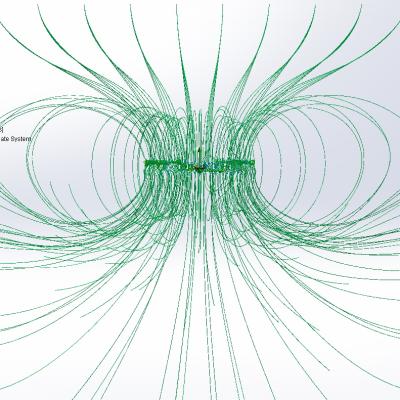

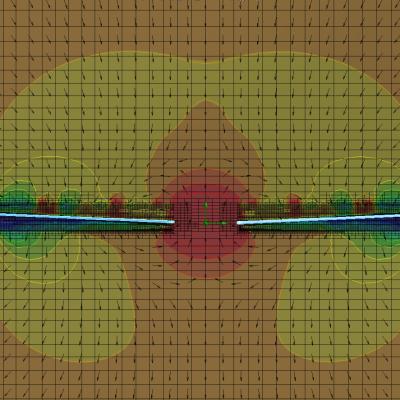

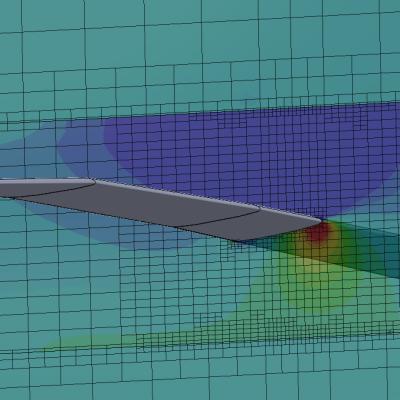

Today's NAE rotor blades for helicopters are the result of aerodynamic, technological and material developments started in 1993. Through gradual development, numerous fatigue, ground and flight tests and massive use of CFD analysis and simulation, completely non-standard, very high performance parameters have been achieved. In comparative tests on identical helicopters, the NAE blades show a thrust increase of over 24% at identical power input, with a simultaneous noise reduction of 4-6 dB.

Our equipment enables the development of individual rotor blades according to specific customer specifications. We can perform the necessary aerodynamic and strength calculations, and combine 3D CAD modelling with CFD analyses. We manufacture the moulds, set up the production technology. We produce prototype and serial sheets.

Actually produced sheets:

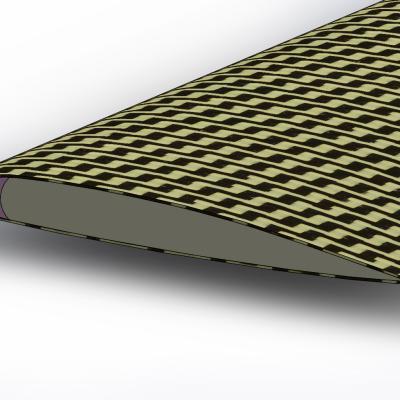

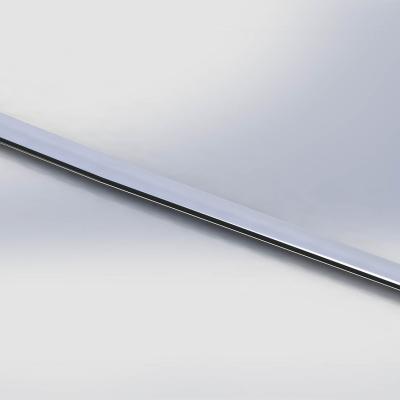

The profile used is asymmetrical, 11% thickness, resulting from in-house development. The twist of the sheet is -7°.

The NAE sheets are manufactured in high-precision aluminium moulds defining their profile, plan and twist. With the use of root inserts, the concept and geometry of the leaf suspension can be changed according to customer specifications.

Manufacturing processes are used to achieve minimal weight differences between sheets in a set. The manufacturing tolerance for weight difference between leaves in a set is +- 1.5 grams. The tolerance of the position of the centre of gravity along the sheet is +- 1,5 mm. These values guarantee minimum operating vibrations.

The design of the rotor blades must be strong, rigid and durable enough to withstand the forces generated by rotational, mass, inertial, frequency and aerodynamic loads.

Modern technology and materials allow rotor blades to be manufactured with high strength and durability, while at the same time high inertia can be achieved at low mass. This, together with advanced aerodynamics, leads to better helicopter performance, lower fuel consumption, higher efficiency and longer rotor blade life.

Today's NAE rotor blades for helicopters are the result of aerodynamic, technological and material developments started in 1993. Through gradual development, numerous fatigue, ground and flight tests and massive use of CFD analysis and simulation, completely non-standard, very high performance parameters have been achieved. In comparative tests on identical helicopters, the NAE blades show a thrust increase of over 24% at identical power input, with a simultaneous noise reduction of 4-6 dB.

Our equipment enables the development of individual rotor blades according to specific customer specifications. We can perform the necessary aerodynamic and strength calculations, and combine 3D CAD modelling with CFD analyses. We manufacture the moulds, set up the production technology. We produce prototype and serial sheets.

Actually produced sheets:

- Sheet length 1.615 mm, profile depth 130 mm. Application for rotors up to 4 m diameter

- Sheet length 2.503 mm, profile depth 190 mm. Use for rotors up to 7 m diameter

- JET sheet variant B.

The profile used is asymmetrical, 11% thickness, resulting from in-house development. The twist of the sheet is -7°.

The NAE sheets are manufactured in high-precision aluminium moulds defining their profile, plan and twist. With the use of root inserts, the concept and geometry of the leaf suspension can be changed according to customer specifications.

Manufacturing processes are used to achieve minimal weight differences between sheets in a set. The manufacturing tolerance for weight difference between leaves in a set is +- 1.5 grams. The tolerance of the position of the centre of gravity along the sheet is +- 1,5 mm. These values guarantee minimum operating vibrations.

Ing. Jan Námisňák, CSc.

Managing Director

"As an aerospace researcher, I understand the importance and key role of rotor blades in the vertical and horizontal movement of a helicopter. They represent not only a symbol of technical excellence, but also a connection to the infinite space of the sky. For me, each rotor blade is like a glimpse of the wings of a bird, which allow take-off and freedom of flight. I see in them a harmony between design and functionality that fills me with admiration and respect as an engineer and aviation enthusiast. I imagine the rotor blades spinning endlessly over the landscape, creating a symphony of movement and elegance that recalls the power of human invention and the desire to explore new horizons."