ROTOR TECHNOLOGY

Nyala - Innovative propulsion for the best performance in the helicopter world!

Nyala, a name inspired by the African antelope, carries the spirit of freedom and pilgrims. Just as these elegant antelopes roam the vast savannahs of Africa, our helicopter soars over the landscape without boundaries or limits. Like the running antelope, our helicopter symbolizes strength, dynamism, elegance and freedom.

The Nyala is a two-seat helicopter with a twin-bladed rotor powered by a jet engine. The necessary volume and air pressure is provided by a seven-cylinder, four-stroke, 4.7 dm3 radial combustion engine. The engine is driven by a centrifugal compressor via an acceleration stage. Thanks to mechanical supercharging, where the loss of power with altitude is limited, the helicopter achieves considerable range and, thanks to the reactive propulsion, exceptional climbability. The propulsion concept ensures high reliability with a minimum of mechanical parts. Low engine operating speeds in the range of 2 - 3,000 RPM together with an efficient exhaust system produce a pleasantly deep, low intensity engine soundtrack both near the ground and at altitude.

The pressurization system has been designed with maximum use of CFD (Computer Fluid Design) to achieve the optimum combination of the required propellant compression ratio with minimum accompanying heating of the air conveyed through the rotor system to the multi-flow propulsion nozzles. In contrast to the solutions used on machines with "jetrotors" in the past, this results in a significantly lower temperature load on all components. The cold/hot mode of operation of the jet system and its thrust is determined by the digital control system according to the flight mode. The control electronics can be deactivated/activated at the pilot's option.

Due to the rotor drive principle, the gearbox and associated systems including lubrication are completely absent, and there is no need for a tail compensating rotor or other compensation system.

Because there is no torque transfer between the motor and rotor, the normal development of resonances is absent and vibration is minimized. Because of the lack of mechanical linkage between the airframe and rotor (except for the rotor bearings themselves), two common causes of accidents in conventional helicopters are completely eliminated. The first are failures of the tail rotor, its transmissions and associated gears, including failures of the associated oil system. The second category of completely eliminated accidents are sideways and forward rollovers of conventional helicopters when the helicopter is untethered from the ground, accompanied by subsequent rotor-to-ground collisions and complete destruction of the rotor and machine.

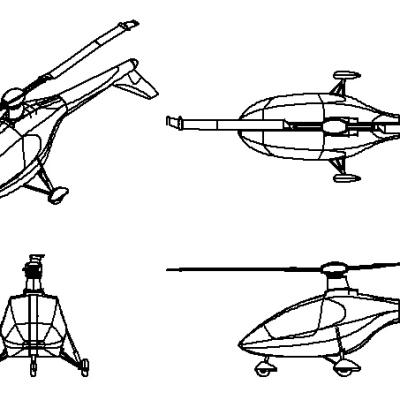

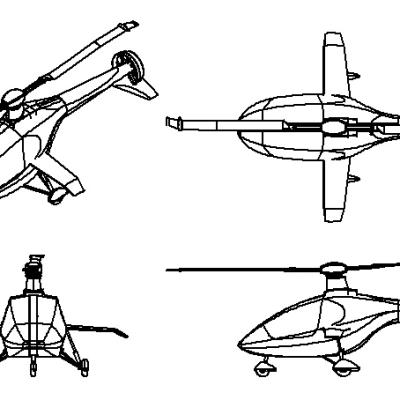

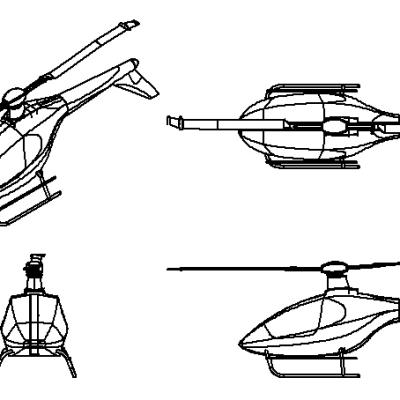

The momentless linkage between the fuselage and rotor allows the use of a practical three-wheeled landing gear, with suspension wheels, facilitating ground transport and handling relative to conventional skid landing gear, and range during autorotation. For conservative users, a standard skid landing gear is available.

Rotor control is handled by dual cyclic controls leading from the rotor directly above. Thus, there are no gears or rods in the rotor control system and there is no steering play. The directional control uses the proprietary patented CoCoMo system in a symmetrized design, where the pressures on the tail spar surface are balanced The BONGO Helicopter (nadc.cz), The BONGO Helicopter (nadc.cz).

The rotor blades are suspended with full freedom of movement in the vertical plane, i.e. in the "flapping" plane. The rotor head itself is connected to the support shaft via a full 3D gimbal. There is thus no possibility of fatal accidents from "locking" of the rotor cradle against the rotor shaft, i.e. a hazard inherent in the 2D cradle system design used almost without exception on conventional UL and light helicopters. The rotor can be folded for easy storage.

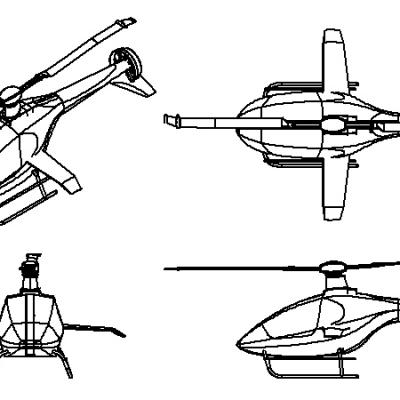

Conceptually, the Nyala in the HP (High Performance) version allows the installation of a carrier wing, which significantly lightens the rotor at higher flight speeds. At the same time, the tail section is directly designed for the installation of a pusher blower to increase flight and operational performance. The whole structure is adequately reinforced in the HP version due to significantly higher flight performance. According to the design, the machine is either in the ULH category (Mtow 450 kg) or a light helicopter with Mtow up to 600 kg.

| Technical specifications Nyala / Nyala HP | |

| Length | 5.40 m |

| Height | 2.25 m |

| Width (fuselage/undercarriage/wing) | 1.31 / 2.17 / 3.70 m |

| Rotor diameter | 6.60 / 6.80 m |

| Engine | Four-stroke, radial VM NY |

| Engine power | 124 HP / 91 kW |

| Empty weight | 242 / 295 kg |

| Maximum take-off weight | 450 kg / 550 kg |

| Maximum speed | 225 / 305 km/h |

| Cruising speed | 185 / 255 km/h |

| Endurance | 2.5 / 3.5 h |